-

NHL players will compete at Olympics, says international ice hockey chief

NHL players will compete at Olympics, says international ice hockey chief

-

Kohli surpasses Sangakkara as second-highest scorer in international cricket

-

Young mother seeks five relatives in Venezuela jail

Young mother seeks five relatives in Venezuela jail

-

Arsenal villain Martinelli turns FA Cup hat-trick hero

-

Syrians in Kurdish area of Aleppo pick up pieces after clashes

Syrians in Kurdish area of Aleppo pick up pieces after clashes

-

Kohli hits 93 as India edge New Zealand in ODI opener

-

Trump tells Cuba to 'make a deal, before it is too late'

Trump tells Cuba to 'make a deal, before it is too late'

-

Toulon win Munster thriller as Quins progress in Champions Cup

-

NHL players will complete at Olympics, says international ice hockey chief

NHL players will complete at Olympics, says international ice hockey chief

-

Leeds rally to avoid FA Cup shock at Derby

-

Rassat sweeps to slalom victory to take World cup lead

Rassat sweeps to slalom victory to take World cup lead

-

Liverpool's Bradley out for the season with 'significant' knee injury

-

Syria govt forces take control of Aleppo's Kurdish neighbourhoods

Syria govt forces take control of Aleppo's Kurdish neighbourhoods

-

Comeback kid Hurkacz inspires Poland to first United Cup title

-

Kyiv shivers without heat, but battles on

Kyiv shivers without heat, but battles on

-

Salah and fellow stars aim to deny Morocco as AFCON reaches semi-final stage

-

Mitchell lifts New Zealand to 300-8 in ODI opener against India

Mitchell lifts New Zealand to 300-8 in ODI opener against India

-

Iran protest death toll rises as alarm grows over crackdown 'massacre'

-

Malaysia suspends access to Musk's Grok AI: regulator

Malaysia suspends access to Musk's Grok AI: regulator

-

Venezuelans await release of more political prisoners, Maduro 'doing well'

-

Kunlavut seals Malaysia Open title after injured Shi retires

Kunlavut seals Malaysia Open title after injured Shi retires

-

Medvedev warms up in style for Australian Open with Brisbane win

-

Bublik powers into top 10 ahead of Australian Open after Hong Kong win

Bublik powers into top 10 ahead of Australian Open after Hong Kong win

-

Sabalenka fires Australian Open warning with Brisbane domination

-

In Gaza hospital, patients cling to MSF as Israel orders it out

In Gaza hospital, patients cling to MSF as Israel orders it out

-

New protests hit Iran as alarm grows over crackdown 'massacre'

-

Svitolina powers to Auckland title in Australian Open warm-up

Svitolina powers to Auckland title in Australian Open warm-up

-

Keys draws on happy Adelaide memories before Australian Open defence

-

Scores of homes razed, one dead in Australian bushfires

Scores of homes razed, one dead in Australian bushfires

-

Ugandan opposition turns national flag into protest symbol

-

Bears banish Packers, Rams survive Panthers playoff scare

Bears banish Packers, Rams survive Panthers playoff scare

-

'Quad God' Malinin warms up for Olympics with US skating crown

-

India eyes new markets with US trade deal limbo

India eyes new markets with US trade deal limbo

-

Syria's Kurdish fighters agree to leave Aleppo after deadly clashes

-

New York's Chrysler Building, an art deco jewel, seeks new owner

New York's Chrysler Building, an art deco jewel, seeks new owner

-

AI toys look for bright side after troubled start

-

AI pendants back in vogue at tech show after early setback

AI pendants back in vogue at tech show after early setback

-

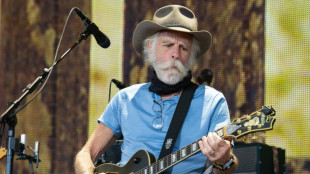

Grateful Dead co-founder and guitarist Bob Weir dies aged 78

-

Myanmar votes in second phase of junta-run election

Myanmar votes in second phase of junta-run election

-

'One Battle After Another' heads into Golden Globes as favorite

-

Rams survive Panthers scare to advance in NFL playoffs

Rams survive Panthers scare to advance in NFL playoffs

-

Rallies across US after woman shot and killed by immigration agent

-

Egypt dump out holders Ivory Coast as Nigeria set up AFCON semi with Morocco

Egypt dump out holders Ivory Coast as Nigeria set up AFCON semi with Morocco

-

Rosenior salutes 'outstanding' start to Chelsea reign

-

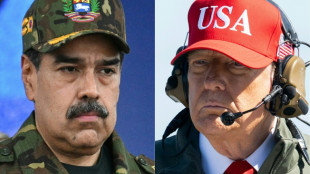

Maduro loyalists stage modest rally as Venezuelan govt courts US

Maduro loyalists stage modest rally as Venezuelan govt courts US

-

Byrne late penalty fires Leinster into Champions Cup last 16 after 'ding-dong' battle

-

Rosenior makes flying start as Chelsea rout Charlton in FA Cup

Rosenior makes flying start as Chelsea rout Charlton in FA Cup

-

Rallies across US against shooting of woman by immigration agent

-

Salah closer to AFCON glory as Egypt dethrone champions Ivory Coast

Salah closer to AFCON glory as Egypt dethrone champions Ivory Coast

-

O'Neil ends 'crazy three days' with Strasbourg cup canter

How to develop perfect battery systems for complex mobile solutions

Using a 3-step-strategy ANSMANN defines the perfect battery pack and charger for each mobile device

(Assamstadt/Bromma/Oslo/Lieusaint, 19-08-2025) Sometimes they combine supercaps with lithium hybrid storage systems; other times they search for the best battery cell for a specific task profile by using their BatteryLab and AI-systems. As mentioned in several publications before: Whatever it takes, Ansmann Group's battery system experts take a broad 3-step-approach, when it comes to finding the optimized battery and charging system for an application - like for example Driverless Transportation Systems (DTS) and Automated Guided Vehicle Systems (AGVs) or Autonomous Mobile Robots (AMRs).

++ Hybrid energy storage of supercaps and LiIon-Technology

How does it work to create a perfect customized battery pack? Step one: dare to think out of the box. A new hybrid storage system for AGVs and AMR , designed by ANSMANN and the IFL Karlsruhe (Institut für Fördertechnik und Logistiksysteme of KIT-Karlsruhe), p.ex. combines the best of two energy storage worlds: supercap capacitors and lithium-ion (LiIon) battery cells. This creates a highly efficient energy storage system, specifically for the needs of a logistic system with AGVs and AMRs. When the so-called double-layer capacitors and battery cells are skillfully combined, the new solution is 50 percent lighter, permanently available and has three times the service life of previous battery applications in AGVs.

The reason for this is, that supercaps can be quickly charged to 95 percent within 30 seconds at precisely located decentralised charging points. The vehicle is then ready for its next tour and can successively charge the conventional battery module. This supplies the vehicle with energy for longer distances, which cannot be covered by the supercap alone. The result: a perfect, extremely energy efficient hybrid energy storage system for mobile logistic solutions - which is almost half the size with up to 80 percent less battery cells and requires less capacity for identical applications than normal LiIon systems would need.

++ Cell preselection in the new Ansmann battery laboratory

Second, it is crucial for each mobile solution, to identify the best cells to be used in its battery pack. Therefor hundreds of different cells - over 300 round cell types, 60 prismatic and 40 others yet - are recorded in the ANSMANN cell database. For more than two years now, a team of ANSMANN experts is systematically searching for new cell types worldwide and tests them for unusual parameters.

The reason for the company's decision to invest in and systematically expand cell measurement and benchmarking in the form of a "battery laboratory" is clear: The number of cell sizes is constantly increasing. Same time, the number of cell chemistries and cell manufacturers is increasing. However, the cell manufacturers' data sheets often only reveal a limited part of the truth and their data was collected only under ideal conditions. So it doesn't tell anything for example about very important selection criteria like the behavior of a cell in its aging process.

Dark side: The use of unsuitable cells can have a significant negative impact on the performance and service life of a battery pack and the mobile solution it is used in. Whatever the critical selection criteria had been, be it current output capability, ability to push the systems acceleration or other: the performance of the battery pack is impaired. Through careful, preventive cell selection, complaining reasons are minimized and the warranty period for the unaffected runtime of the battery pack can be extended to reduce costs.

++ Third step is the use of a self-developed Artificial Intelligence (AI) Tool

And even more - step three: For deciding about the best cell forms for the specific solution and speeding up time-to-market of its customers, ANSMANN Industrial Solutions has developed it's own AI-tool, that helps to optimize the pack designs and formats more quickly.

For more than three decades, ANSMANN has been at the forefront as the world's leading expert in battery, accumulator, charging, drive and lighting technology. The more than 400 employees support their industrial customers in the complete development process of their mobile electronic devices and vehicles: from consulting through development, testing and distribution to cell and battery system recycling. More information: ANSMANN Industrial Solutions

Company description

The Ansmann Group is known in many European countries for more than 30 years for its particularly safe, technically pioneering and yet cost effective solutions for private and industrial applications. Those include medical equipment - as ANSMANN production is certified to the EN ISO 13485 medical standard, battery components for e-wheelchairs, e-bikes, battery-powered forestry as well as gardening powertools and various kinds of small e-vehicles and types of equipment.

The company operates a production facility and central logistics centre at its headquarters in Assamstadt and offices in France, Sweden, Norway and the UK. The ANSMANN UN test centre and a BatteryLab and test facility for cells and battery systems can run all necessary tests and checks to ensure the transportability, safety and recyclability of battery packs and solutions.

Company-Contact

Ansmann AG

Christopher Vogt

Industriestr. 10

97959 Assamstadt

+49 6294 4204-0

https://www.ansmann.de

Press

Comm:Motions - Text & PR

Miriam Leunissen

Hechtseestr 16

83022 Rosenheim

+49 174 3005749

https://www.comm-motions.com

S.Barghouti--SF-PST